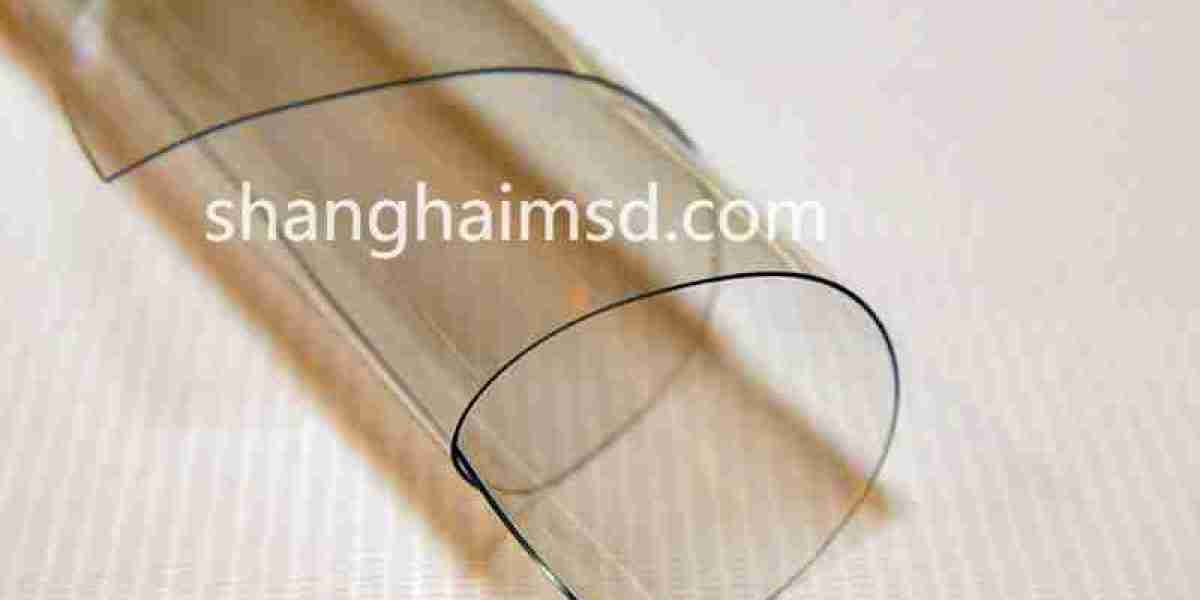

In transparent polymer films, visual performance is inseparable from internal structural stability, and MSD PVC Super Clear Film is often referenced in technical discussions where clarity must coexist with durability. When PVC films are expected to perform under continuous handling, environmental exposure, or secondary processing, their material behavior reveals much more than surface-level transparency.

The foundation of super clear PVC film lies in molecular compatibility. PVC resin alone does not deliver flexibility or clarity; instead, performance emerges from the interaction between resin chains and plasticizers. Compatibility at the molecular level determines whether the film remains uniformly transparent or develops haze over time. Poorly matched formulations can lead to plasticizer migration, resulting in surface tackiness or clouding. Stable systems maintain transparency because the plasticizer remains evenly distributed within the polymer matrix throughout the film’s service life.

Thermal behavior is another critical factor influencing material stability. Super clear PVC film often undergoes secondary heat exposure during lamination, thermoforming, or sealing. Each heat cycle places stress on the polymer structure. Films with balanced thermal resistance exhibit minimal shrinkage and retain optical clarity after reheating. Heat aging tests simulate these conditions by exposing samples to elevated temperatures for extended periods, revealing how color, flexibility, and transparency evolve over time.

From a processing perspective, internal stress management plays a key role. During film formation, molecular orientation occurs as molten PVC transitions into a solid state. If cooling is uneven or too rapid, residual stress becomes trapped within the film. These stresses may not be visible initially but can manifest later as curling, edge distortion, or localized whitening. Controlled cooling profiles help relax molecular chains, promoting dimensional stability and long-term visual consistency.

Super clear PVC film is frequently used in applications requiring repeated contact and movement. In protective covers and flexible overlays, abrasion resistance becomes as important as transparency. Surface durability is evaluated through rubbing and scratch tests, which measure how well the film maintains clarity after friction. Films with optimized surface smoothness and internal cohesion resist micro-scratches that would otherwise scatter light and reduce transparency.

Another important performance dimension is resistance to environmental factors. Exposure to humidity, light, and airborne chemicals can gradually alter film properties. Moisture absorption tests assess dimensional changes in high-humidity environments, while light exposure tests examine yellowing or loss of clarity. Films designed for indoor and semi-outdoor use must balance UV resistance with transparency, ensuring visual performance remains stable during extended exposure.

Application reliability also depends on how the film interacts with other materials. In composite structures, super clear PVC film may be bonded to fabrics, boards, or foams. Adhesion strength is influenced by surface energy and chemical compatibility. Peel tests and shear tests provide insight into bonding performance, ensuring the film remains securely attached without delamination during use. Stable adhesion contributes not only to mechanical integrity but also to consistent appearance.

Shanghai MSD integrates these performance considerations into its material selection and quality verification approach. By focusing on how super clear PVC film behaves across different application scenarios, the company supports customers who require predictable results rather than purely visual appeal. This approach is especially relevant in applications where film failure leads to functional or aesthetic issues downstream.

Testing protocols serve as the bridge between material design and application reliability. Optical measurements quantify light transmission and haze, while mechanical tests confirm flexibility and strength. Environmental simulations expose potential weaknesses before products reach the market. Together, these evaluations provide a comprehensive understanding of how super clear PVC film performs under real operating conditions.

For readers interested in further technical perspectives and application-driven insights related to Shanghai MSD’s transparent film solutions, additional reference material is available at

https://www.shanghaimsd.com/news/industry-news/pvc-super-clear-film-the-ultimate-transparent-solution-for-versatile.html .