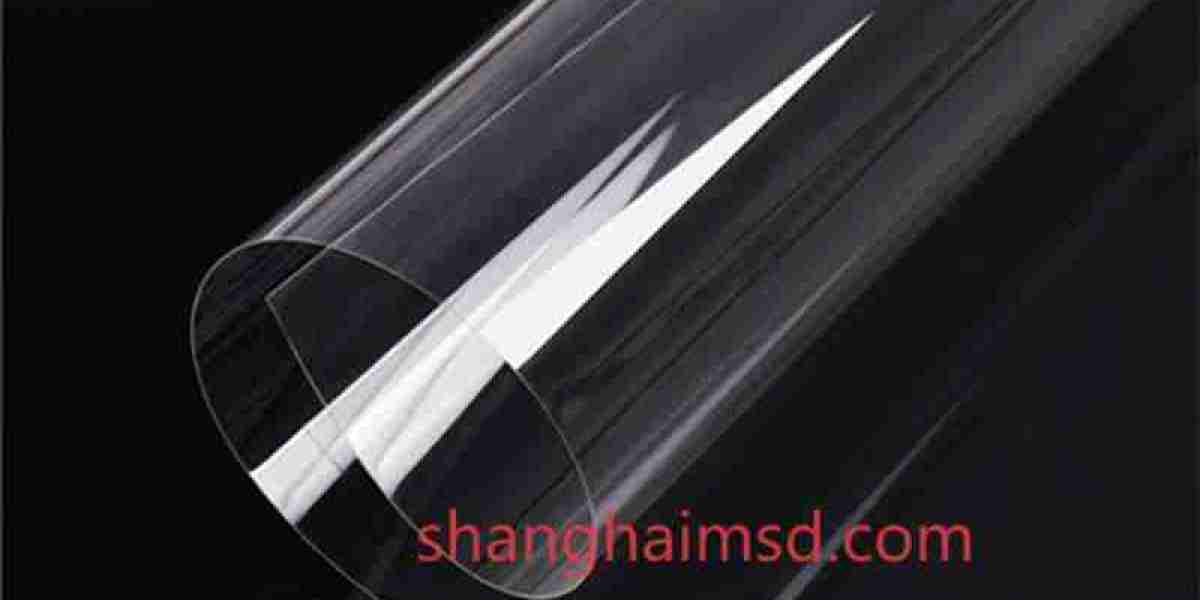

In industries where visual clarity and material reliability must coexist, transparent polymer films play an increasingly important role in product design and functional performance. Among these materials, MSD PVC Super Clear Film is widely discussed for its balanced combination of optical clarity, process stability, and adaptability across different manufacturing environments. Its structure and production logic reflect the evolving demands of modern packaging, protective, and display-related applications.

PVC super clear film is engineered to achieve high transparency through precise control of raw material formulation and processing conditions. The base resin selection, combined with carefully balanced plasticizers and stabilizing agents, allows the film to maintain clarity while retaining flexibility and dimensional stability. Unlike conventional transparent films, super clear PVC requires strict control over impurities and dispersion to prevent haze, bubbles, or surface distortion that could compromise visual quality.

The processing of PVC super clear film typically relies on advanced calendering or extrusion techniques, where temperature control and pressure uniformity are critical. During production, molten PVC compounds are formed into thin sheets under tightly regulated conditions to ensure even thickness and smooth surface finish. Minor deviations in processing parameters can lead to optical inconsistencies, making process control a central focus. Shanghai Ming Shida International Trading Company emphasizes coordination with manufacturing partners to maintain stable processing standards and consistent output quality.

Surface smoothness is a defining characteristic of super clear PVC film. A uniform surface not only enhances transparency but also improves compatibility with secondary processes such as printing, lamination, or thermoforming. The absence of surface defects allows the film to be used in applications where direct visual contact with underlying products is required. This makes the material suitable for packaging displays, protective covers, and interior decorative elements that rely on visual presentation.

Application versatility is one of the key advantages of PVC super clear film. In packaging, it provides product visibility while offering protection against dust, moisture, and handling damage. In industrial settings, the film is used as a protective layer for surfaces or components that require monitoring without removal. It is also applied in stationery, decorative panels, and flexible enclosures where transparency and formability are essential. The ability to adapt to different thicknesses and processing methods supports diverse usage scenarios.

Performance evaluation plays an important role in ensuring reliability across applications. Optical clarity testing measures light transmission and haze levels to verify visual performance. Tensile strength and elongation tests assess mechanical flexibility and resistance to tearing during handling or forming. Surface adhesion tests are conducted when the film is intended for lamination or printing, ensuring compatibility with inks or bonding layers. These tests help align material properties with practical application requirements.

Environmental stability is another consideration in PVC super clear film performance. Exposure to temperature variations, light, and humidity can affect transparency and flexibility over time. Controlled formulation and stabilization help reduce the risk of discoloration or brittleness during use. Shanghai Ming Shida International Trading Company pays close attention to performance consistency by ensuring that material specifications meet the environmental expectations of target applications.

From a processing standpoint, PVC super clear film offers advantages in fabrication efficiency. The film can be easily cut, heat-sealed, or formed without significant loss of clarity. This supports efficient integration into automated production lines and custom fabrication workflows. Its processing compatibility reduces material waste and supports consistent quality in finished products.

Shanghai Ming Shida International Trading Company continues to support the development and application of transparent PVC materials by focusing on material coordination, process stability, and performance evaluation. Through close collaboration with manufacturing partners, the company helps ensure that super clear PVC film meets the visual and functional demands of modern industries. More information on the characteristics and applications of PVC super clear film can be found at https://www.shanghaimsd.com/news/industry-news/pvc-super-clear-film-the-ultimate-transparent-solution-for-versatile.html .