In the competitive global packaging market, where cost control and production efficiency are critical for profitability, buyers carefully evaluate options like the Cap Compression Molding Machine Price, which reflects the balance between advanced features and long-term value in cap manufacturing equipment. This pricing structure appeals to manufacturers seeking high-output systems that lower per-unit costs through reduced material and energy consumption. The investment returns quickly as the machine's continuous operation minimizes downtime compared to intermittent processes. Tai Zhou Chuang Zhen Machinery Manufacturing sets competitive benchmarks by offering transparent pricing tiers based on cavity numbers and automation levels, allowing clients to select configurations that match budget constraints without sacrificing quality. As bottled product consumption rises in emerging economies, the focus on affordable yet reliable machinery intensifies, making price a key decision factor alongside performance.

The Cap Compression Molding Machine Price is influenced by market demand for systems that support diverse cap types while maintaining economic viability. Rising resin costs push producers toward equipment that maximizes yield, justifying premium pricing for models with higher precision. Tai Zhou Chuang Zhen Machinery Manufacturing structures pricing to include comprehensive after-sales support, adding value through training and maintenance packages that reduce ownership expenses over time. This approach attracts mid-sized bottlers transitioning from manual to automated lines, where initial investment is weighed against labor savings. Seasonal demand fluctuations in beverage sectors encourage flexible pricing models, such as leasing options that spread costs. Export-oriented factories benefit from duty-optimized pricing, facilitating entry into international markets with compliant machinery.

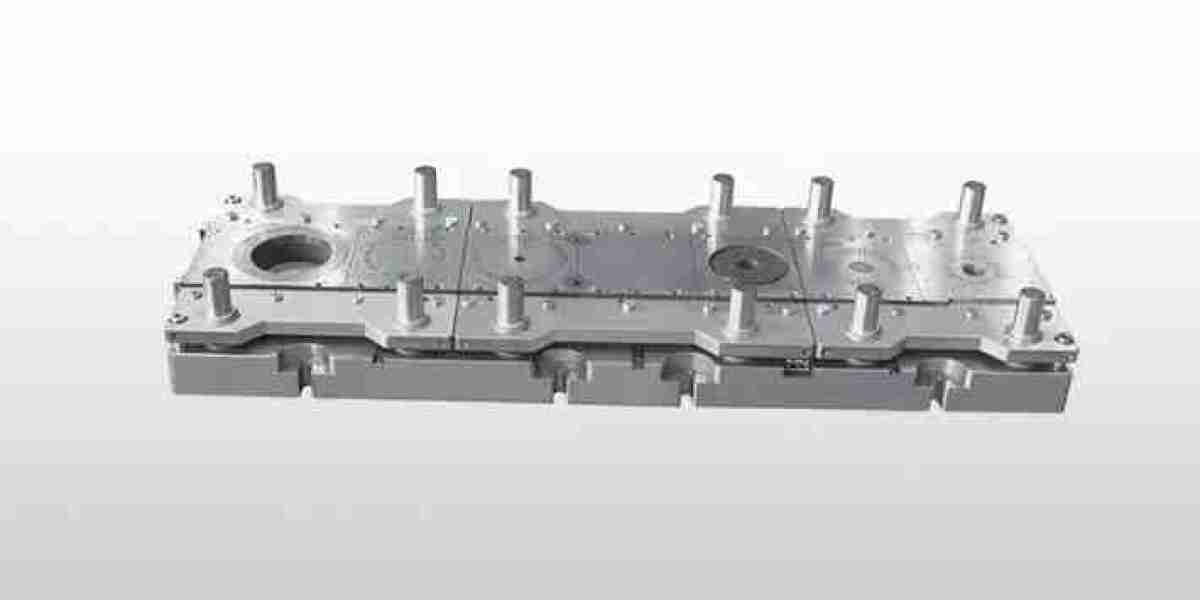

Technological innovations contributing to favorable pricing include compact designs that reduce factory footprint, lowering installation and facility modification expenses. Integrated control systems consolidate functions, eliminating need for separate peripherals that inflate total costs. Tai Zhou Chuang Zhen Machinery Manufacturing incorporates durable components with extended warranties, deferring replacement expenditures and stabilizing long-term pricing predictability. Energy-efficient drives not only cut operational bills but also qualify buyers for green incentives that offset purchase price. Modular construction allows future upgrades without full replacement, protecting initial investment as production needs evolve.

Application scenarios demonstrate price justification across industries, from carbonated drinks requiring high-volume standard caps to specialty sauces needing custom dispensing closures. In the water bottling segment, affordable multi-cavity machines enable competitive pricing for basic screw caps. Tai Zhou Chuang Zhen Machinery Manufacturing tailors pricing for hot-fill compatible models used in juice production, where heat-resistant tooling adds value without disproportionate cost increase. Pharmaceutical vial caps demand sterility-focused designs, with pricing reflecting cleanroom-ready features. Cosmetic jar lids incorporate decorative elements, balanced by efficient molding that keeps unit prices low.

Performance advantages that support the pricing model include faster cycle times that boost daily output, directly impacting revenue generation. Consistent cap weight control reduces material overrun, delivering savings that accumulate rapidly. Tai Zhou Chuang Zhen Machinery Manufacturing engineers machines with intuitive interfaces that shorten operator training, minimizing indirect costs. Robust build quality ensures minimal breakdowns, preserving production schedules and avoiding expensive interruptions. Advanced cooling channels accelerate solidification, enabling higher throughput without additional energy spend.Those interested in exploring competitive options for closure equipment can find detailed information at https://www.capping-machine.net/product from Tai Zhou Chuang Zhen Machinery Manufacturing.