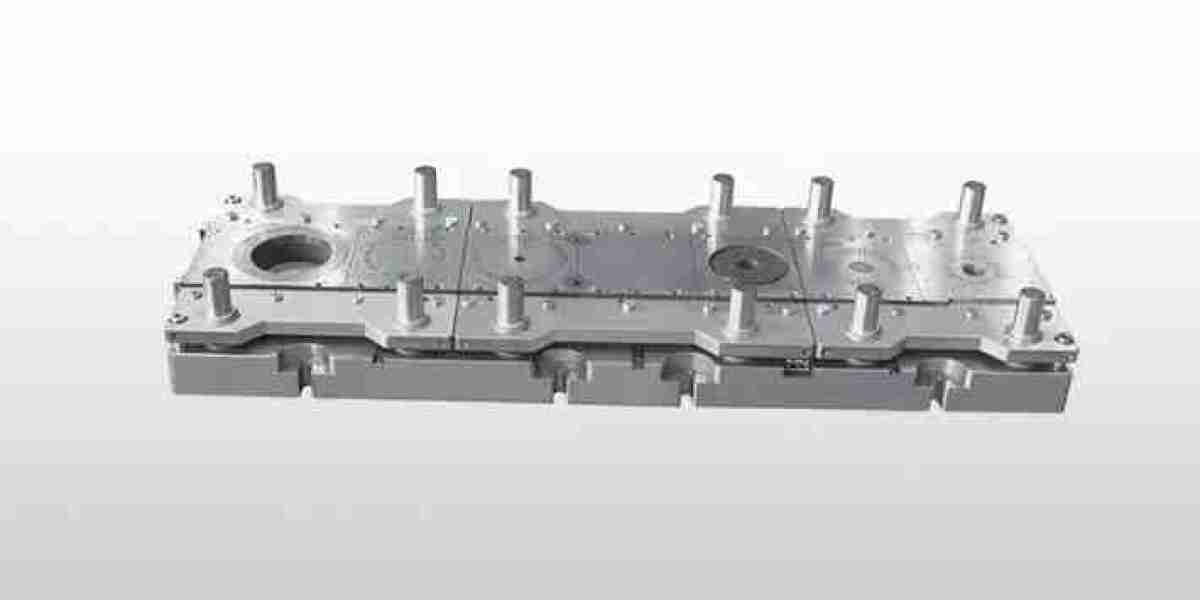

Precision plays a defining role in manufacturing, especially when producing components that demand accuracy and consistency. A Precision Stamping Mold is at the heart of this process, shaping metal sheets into parts with exact dimensions and smooth finishes. Whether it’s for electric motor cores, electronic connectors, or structural components, every detail in a mold determines the stability and quality of mass production.

A professional Precision Stamping Mold Company focuses on turning complex engineering requirements into practical, efficient solutions. Their expertise lies in designing and producing molds that maintain dimensional consistency even under high-speed, high-volume conditions. For example, a well-engineered mold can perform hundreds of millions of punches while keeping burr height under 0.05mm. This level of precision supports industries that cannot afford deviations in their assembly lines.

Customization is another reason why manufacturers rely on a Precision Stamping Mold Company. Different applications call for different mold configurations—single-row, double-row, or even multi-row layouts. When clients require variations in stator and rotor lamination sizes, such as from Φ12 to Φ720mm, customization becomes essential. Functions like self-locking slots, skewed designs, or punched step holes can be integrated directly into the mold structure to meet unique production needs.

Behind each Precision Stamping Mold is advanced engineering and material selection. High-strength steels such as Cr12MOV and DJ40 are used to extend tool life and maintain cutting accuracy. During manufacturing, specialized polishing and wire-cutting processes are applied to eliminate oxidation layers, keeping edges sharp and consistent. These details directly influence the mold’s stability, speed, and lifespan in continuous production.

A trusted Precision Stamping Mold Company not only delivers the mold itself but also offers technical support throughout the production cycle. This includes testing during the running-in period, misfeed protection devices for reliability, and spare part preparation to reduce downtime. For clients, this partnership means greater confidence in their manufacturing flow and long-term cost efficiency.

Choosing the right Precision Stamping Mold Company is ultimately about collaboration. When a manufacturer understands both the technical and operational sides of production, they provide molds that work seamlessly with customer equipment. The result is steady output, lower maintenance costs, and consistent quality—proof that precision is not just a technical standard but a foundation of sustainable manufacturing success.