A high-speed progressive stamping die is widely used in factories that produce metal parts in large quantities with stable dimensions. Buyers searching for this solution usually want one thing: steady output without frequent downtime. That's why this tooling type is common in automotive parts, electronics hardware, and industrial components where cycle time matters.

Many people ask what actually makes a High Speed Progressive Stamping Die different from a standard die. The core difference is how multiple forming steps are integrated into one continuous process. Material moves through stations in sequence, allowing punching, bending, and shaping to happen in one run. This setup helps factories keep production moving while maintaining part consistency.

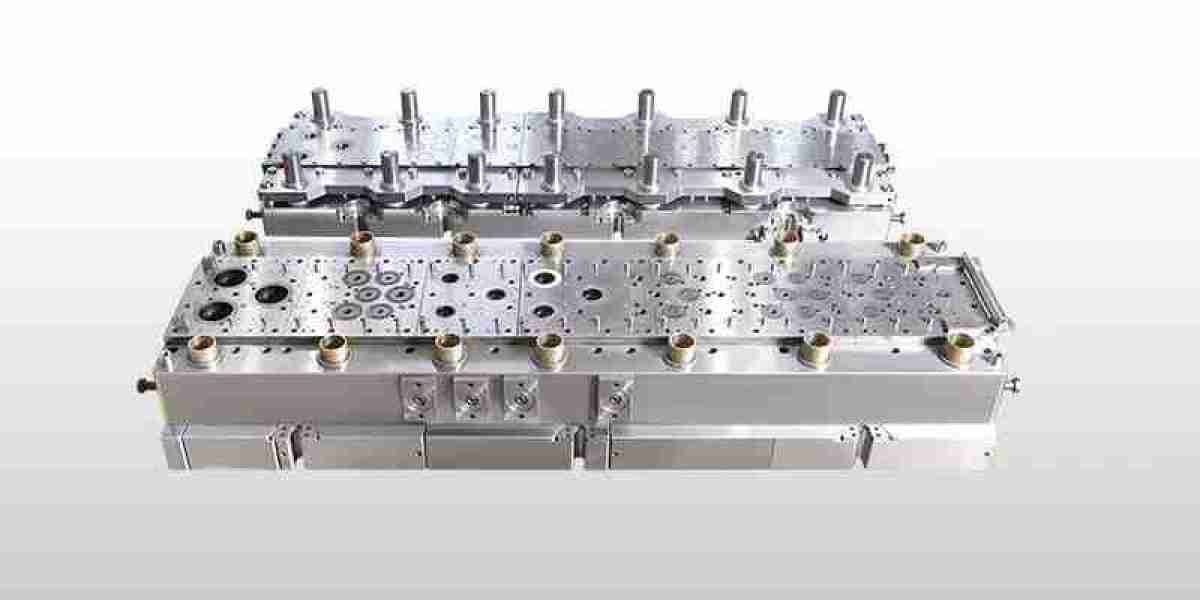

Another common concern is how tooling design affects daily production. A well-designed High Speed Progressive Stamping Die focuses on material flow, strip layout, and tool alignment. These details directly influence stability during high-speed operation. Factories often look for dies that can handle long runs without frequent adjustments, especially when working with thin or complex metal strips.

Customization is another topic buyers care about. Many high-speed progressive stamping die manufacturers offer mold customization services to match specific part drawings and production goals. Mold customization allows tooling to be adjusted for material type, thickness, and press speed. This flexibility helps factories align the die with their existing equipment rather than changing the entire production line.

When evaluating high-speed progressive stamping die manufacturers, buyers often look beyond price. Experience with custom metal mold projects is a strong indicator of capability. Custom metal molds are built to handle repeated cycles and tight tolerances, which is critical for progressive stamping applications. Manufacturers with this background usually understand how tooling behavior changes during continuous operation.

Some buyers also ask whether stainless steel casting molds are related to progressive stamping. While the processes differ, knowledge of stainless steel casting molds demonstrates a manufacturer's familiarity with durable mold materials and dimensional control. This experience can support better decisions when selecting steels and treatments for stamping dies used in demanding environments.