Introduction

Gelatin is a versatile and widely used ingredient in the food, pharmaceutical, and cosmetic industries. It is a natural product derived from collagen, which is found in animal connective tissues. Gelatin has a wide range of applications, including as a gelling agent in food products, as a stabilizer in pharmaceuticals, and in the creation of capsules, coatings, and other cosmetic products. The growing demand for gelatin products in various industries has created an opportunity for establishing a Gelatin Manufacturing Plant. This Gelatin Manufacturing Plant Project Report provides an in-depth analysis of the market potential, manufacturing processes, equipment, and financial considerations for setting up a successful gelatin production facility.

Market Overview and Trends

Increasing Demand for Gelatin

The demand for gelatin has been steadily rising due to its wide-ranging applications in multiple industries. Some of the key drivers of the demand for gelatin include:

- Food Industry: Gelatin is used as a gelling agent in the production of confectioneries, gummies, marshmallows, and desserts. It also serves as a stabilizer in dairy products like yogurt and ice cream.

- Pharmaceutical Industry: Gelatin is used in the manufacturing of soft and hard capsules, as it is safe for consumption and provides a reliable method of delivering medication. Its use in wound dressings and medical products is also increasing.

- Cosmetics and Personal Care: Gelatin is used in the production of face masks, shampoos, and other personal care products due to its hydrating and skin-boosting properties.

- Health and Wellness Products: Gelatin has a growing market in the health and wellness sector, particularly in the production of collagen supplements for improving joint health, skin elasticity, and hair growth.

Get a Free Sample Report with Table of Contents@

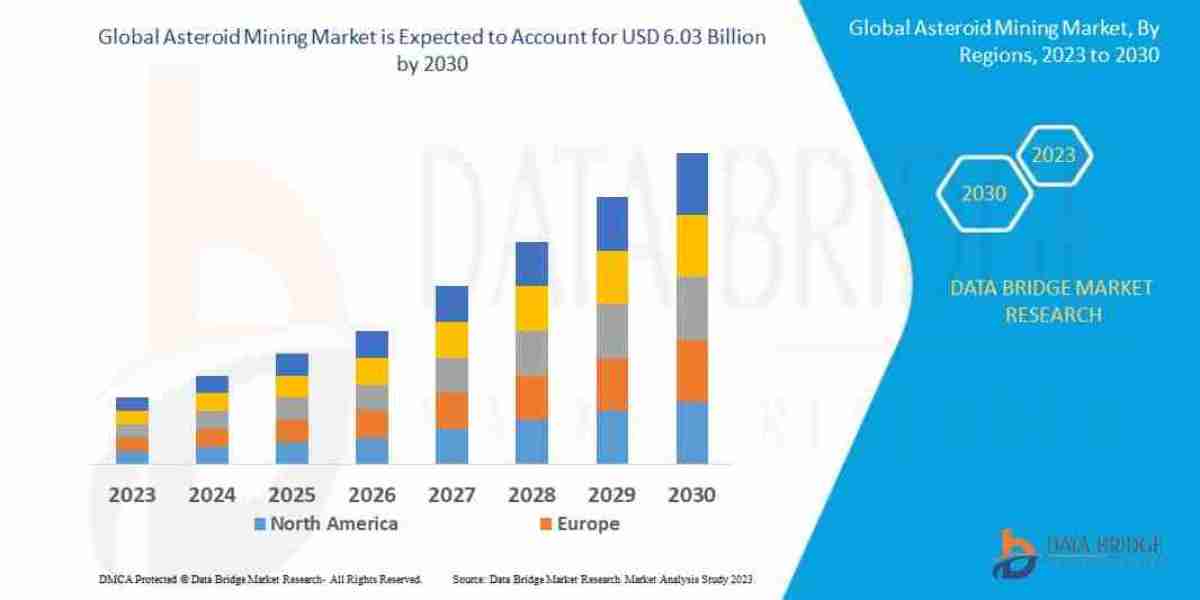

Regional Demand for Gelatin

The demand for gelatin is widespread, with specific regional trends emerging due to varying market dynamics:

- North America and Europe: These regions have a well-established demand for gelatin in the food, pharmaceutical, and cosmetic industries. The increasing preference for natural and sustainable products in these regions has contributed to gelatin's popularity.

- Asia-Pacific: The growing food industry, rising healthcare awareness, and expanding pharmaceutical sector in countries like China, India, and Japan are driving the demand for gelatin.

- Latin America and the Middle East: These regions are witnessing a rise in gelatin consumption due to an increase in disposable incomes, higher demand for processed foods, and greater awareness of health and wellness products.

Manufacturing Process

Gelatin production involves extracting collagen from animal tissues and converting it into a gelatinous substance. The process can be broken down into several key stages:

Raw Materials

- Animal Collagen: The primary raw material for gelatin production is animal collagen, typically sourced from the skins, bones, and connective tissues of pigs, cattle, or fish.

- Water: Water is used to aid in the extraction process and to dissolve the collagen.

- Acids and Alkalis: Certain acids and alkalis may be used during the extraction process to break down the collagen into gelatin.

Gelatin Extraction Process

Pre-treatment of Raw Materials: The first step in the process is cleaning and preparing the raw animal materials. This may involve washing and removing impurities from the skins, bones, and connective tissues.

Acid and Alkali Treatment: The raw materials are treated with acids or alkalis to break down the collagen and facilitate the extraction process. Acid treatment typically takes place for a few days to help dissolve the collagen into a soluble form.

Boiling and Extraction: After pre-treatment, the raw material is boiled to extract the collagen. During boiling, the collagen is dissolved in hot water and forms a gel-like substance.

Purification and Filtration: The extracted gelatin solution is filtered to remove any remaining impurities, fats, and particles. This step ensures the gelatin's purity and clarity.

Concentration: The gelatin solution is concentrated by evaporating excess water. This is done under controlled conditions to avoid the degradation of the gelatin.

Cooling and Gelling: Once concentrated, the gelatin solution is cooled to form a gel. The gelatin may be processed into various forms, such as sheets, granules, or powders, depending on its intended application.

Drying and Packaging: The gelatin is then dried using air dryers or spray dryers to remove any remaining moisture. The final product is packaged according to specifications, ready for distribution.

Equipment and Technology

A Gelatin Manufacturing Plant requires specialized equipment for the extraction, purification, and drying of gelatin. Some of the key equipment includes:

- Pre-treatment Equipment: Washing and cleaning machines are used to prepare the animal collagen for the extraction process.

- Boiling Tanks: Large boiling tanks are required for extracting collagen by heating raw materials in water.

- Filtration Systems: Filtration units remove impurities and fats from the gelatin solution, ensuring a high-quality end product.

- Evaporation Units: These units are used to concentrate the gelatin solution by evaporating excess water.

- Drying Systems: Air dryers or spray dryers are used to dry the gelatin to the desired moisture content.

- Packaging Equipment: After drying, the gelatin is packaged in various forms (powder, granules, or sheets) using automatic packing machines.

Emerging Technologies in Gelatin Manufacturing

- Enzyme-Based Extraction: Advances in enzymatic extraction methods are being explored to improve the yield and quality of gelatin while minimizing the use of chemicals.

- Eco-Friendly Practices: With increasing environmental awareness, manufacturers are adopting sustainable practices such as water recycling and reducing the carbon footprint of production.

- Automation: Automated systems for gelatin extraction, purification, and drying are helping manufacturers improve efficiency, reduce labor costs, and maintain product consistency.

Regulatory Compliance and Certifications

Regulatory Requirements for Gelatin Production

Gelatin production is subject to various regulatory requirements to ensure product safety and quality. These include:

- Food Safety Standards: Gelatin used in food products must comply with food safety standards set by organizations such as the Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA).

- Pharmaceutical Standards: Gelatin used in pharmaceutical applications must meet specific standards for purity, such as those outlined by the United States Pharmacopeia (USP) or the European Pharmacopoeia (EP).

- Cosmetic Standards: Gelatin used in cosmetics must comply with safety regulations set by the FDA and other national regulatory bodies.

- ISO Certifications: Manufacturers can obtain ISO 9001 certification for quality management and ISO 14001 for environmental management, demonstrating their commitment to quality and sustainability.

Environmental Regulations

Gelatin manufacturing involves the use of water, chemicals, and energy, which can have an environmental impact. Manufacturers are required to comply with local environmental regulations related to waste disposal, water usage, and emissions. Implementing waste reduction measures, water recycling, and energy-efficient technologies are essential for minimizing the environmental footprint.

Financial Considerations

Capital Investment

Setting up a Gelatin Manufacturing Plant requires substantial capital investment in infrastructure, machinery, and raw materials. Key capital expenditures include:

- Land and Infrastructure: The cost of land, building the manufacturing facility, and establishing utilities.

- Machinery and Equipment: The cost of specialized equipment for extracting, purifying, drying, and packaging gelatin.

- Raw Materials: The initial procurement of animal collagen, water, and chemicals required for the extraction process.

Operational Costs

Ongoing operational expenses include:

- Raw Material Procurement: The cost of sourcing animal collagen from suppliers, which can fluctuate based on market conditions.

- Labor Costs: Wages for workers involved in the manufacturing, quality control, and maintenance processes.

- Energy and Water Costs: The energy-intensive nature of gelatin production means that electricity and water costs are significant operational expenses.

- Maintenance: Regular maintenance of machinery and equipment to ensure efficient and consistent production.

Revenue Potential

The revenue from a gelatin manufacturing plant depends on factors such as production capacity, product quality, and market demand. Gelatin is a high-demand product, especially in the food, pharmaceutical, and cosmetic industries, making it a profitable business venture.

Supply Chain and Distribution

The distribution of gelatin involves a structured supply chain to ensure timely delivery to customers. Key stages in the supply chain include:

- Raw Material Sourcing: Secure reliable suppliers of animal collagen to ensure a consistent raw material supply.

- Production and Quality Control: The gelatin is produced, tested, and packaged according to customer requirements and industry standards.

- Packaging and Distribution: Gelatin is packaged in different forms (powder, granules, or sheets) and distributed to wholesalers, food manufacturers, pharmaceutical companies, or cosmetic producers.