IMARC Group, a leading market research company, has recently released a report titled "Printed Electronics Market Report by Material (Ink, Substrate), Technology (Inkjet, Screen, Gravure, Flexographic), Device (Display, Photovoltaic, Lighting, RFID, and Others), and Region 2025-2033." The study provides a detailed analysis of the industry, including the global printed electronics market share, trends, size and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Printed Electronics Market Highlights:

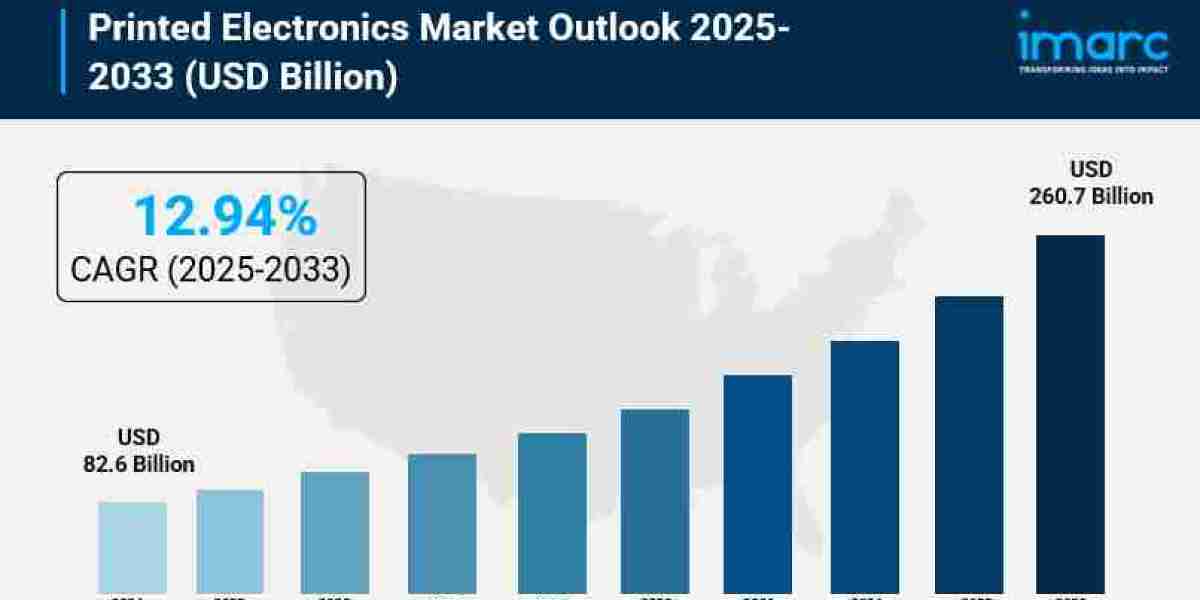

- Printed Electronics Market Size: Valued at USD 82.6 Billion in 2024.

- Printed Electronics Market Forecast: The market is expected to reach USD 260.7 billion by 2033, growing at an impressive rate of 12.94% annually.

- Market Growth: The printed electronics market is experiencing robust growth driven by escalating demand for flexible and lightweight devices and the rapid expansion of IoT technology.

- Technology Integration: Advanced printing technologies like roll-to-roll and inkjet printing are revolutionizing electronics manufacturing with cost-effective, scalable alternatives to traditional methods.

- Regional Leadership: Asia-Pacific commands the largest market share, fueled by massive electronics manufacturing hubs in China, Japan, and South Korea.

- Innovation Focus: Rising investments in research and development are driving breakthroughs in conductive inks, flexible substrates, and next-generation display technologies.

- Key Players: Industry leaders include Agfa-Gevaert N.V., BASF SE, DuPont de Nemours Inc., E Ink Holdings Inc., Molex LLC, and Nissha Co. Ltd., which dominate the market with cutting-edge solutions.

- Market Challenges: Complex integration requirements and the need for high-performance materials present ongoing technical and cost challenges.

Claim Your Free “Printed Electronics Market” Insights Sample PDF: https://www.imarcgroup.com/printed-electronics-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Industry Trends and Drivers:

· The Acceleration of Flexible and Conformable Electronics:

The most meaningful application for printed electronics is thin-film electronics on flexible non-planar substrates in the wearables, smart textiles and soft electronics market, where comfortable, lightweight and strong characteristics are needed. Standard subtractive technology such as etching cannot be used on flexible substrates such as poly(ethylene terephthalate) (PET), poly(ethylene naphthalate) (PEN) or paper because of their fragility and physical characteristics. Conduction, semiconductor and dielectric materials can be deposited on flexible substrates using printing methods (inkjet printing, screen printing, flexography printing). Their applications include ultra-thin, disposable biosensors to monitor health (e.g., hydration patches, ECG sensors), flexible screens (the smartphones of tomorrow), car interiors and smart textiles (with printed heaters or capacitive touch sensors). This requires great progress in material science, the ability to create highly stable and stretchable conductive inks with thin film encapsulation that can withstand bending, twisting and harsh environmental conditions.

· Mass Deployment of Low-Cost Sensors for the IoT:

This amounts to a huge IoT and supply chain digitization market, with billions of items to be tagged all the way down from the individual item or consumer packaged goods (CPG), to the pharmaceutical. Cheap, thin, sometimes even disposable and recyclable electronics will be needed, and silicon can never be that. Printed electronics is the only additive manufacturing technology that offers volume and cost scalability (pennies per unit cost) for commercial applications. There are already printed organic photodetector devices, printed in-memory arrays, and printed functional coatings (e.g., temperature/humidity sensors) that will be printed onto packages, labels, and other substrates in commercial applications. This enables smart packaging to monitor integrity or freshness through the supply chain, moving from basic inventory control applications to real-time asset monitoring using intrinsically low-cost, scalable printing technologies.

· Emphasis on Sustainable and Efficient Manufacturing:

Driven by the trends in sustainability and efficiency, the next radical step in the way we manufacture electronic devices is the use of printed electronics, which has the potential to reduce the material and energy intensity and toxic/corrosive chemicals associated with conventional subtractive printed circuit board (PCB) manufacturing technology. This enables printed electronics to be more sustainable than conventional electronic fabrication; in addition to the intrinsic additive processes (reducing the amount of material use by up to 90% compared to customary subtractive processes), the use of water-based or solvent-free functional inks that can be cured at lower temperatures, all lend themselves to increased demand for manufacturing equipment that can process R2R at speed and in combination with other materials, thus making the whole manufacturing chain faster, less wasteful, and far more environmentally sustainable than customary fabrication processes.

Printed Electronics Market Report Segmentation:

Breakup by Material:

- Ink

- Substrate

Ink dominates the market, accounting for the majority share due to continuous innovations in conductive, dielectric, and optically active ink formulations that enhance functionality across diverse applications.

Breakup by Technology:

- Screen

- Inkjet

- Gravure

- Flexographic

Screen technology holds the largest market share, favored for its reliability in high-volume production and ability to handle diverse substrate materials with consistent quality.

Breakup by Device:

- Display

- Photovoltaic

- Lighting

- RFID

- Others

Display applications represent the leading market segment, driven by explosive demand for flexible OLED displays, e-paper solutions, and curved screen technologies in consumer electronics.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Who are the key players operating in the industry?

The report covers the major market players including:

- Agfa-Gevaert N.V.

- BASF SE

- DuPont de Nemours Inc.

- E Ink Holdings Inc.

- Molex LLC (Koch Industries)

- Nissha Co. Ltd.

- NovaCentrix

- Optomec Inc.

- Palo Alto Research Center Incorporated (Xerox Corporation)

- Vorbeck Materials Corporation

- Ynvisible Interactive Inc.

Ask Analyst For Request Customization: https://www.imarcgroup.com/request?type=report&id=3927&flag=E

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1–201971–6302